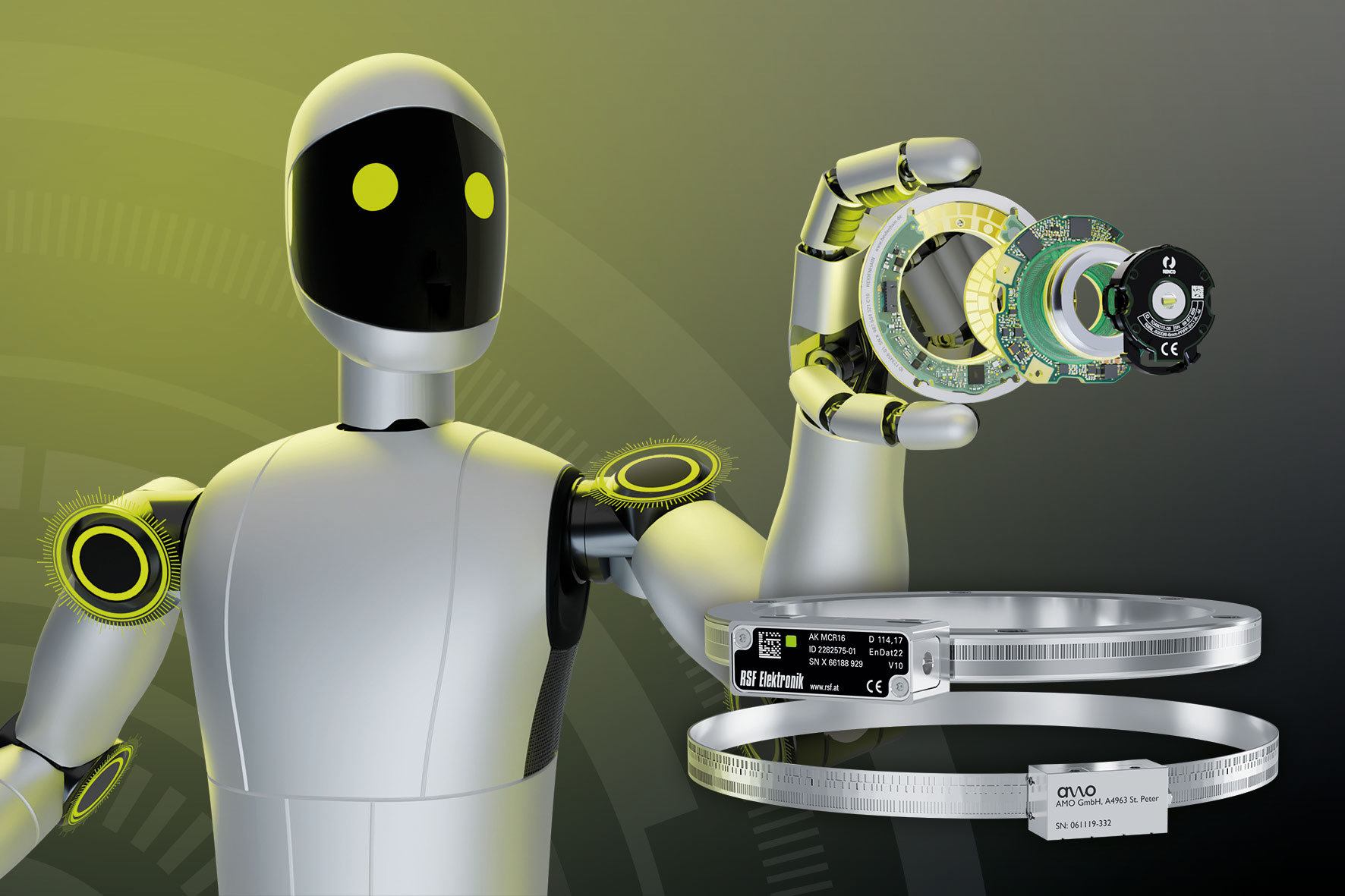

HEIDENHAIN and its brands AMO, RENCO, and RSF will be showcasing innovative motor feedback solutions for automation and robotics at SPS 2025 in Nuremberg, Germany

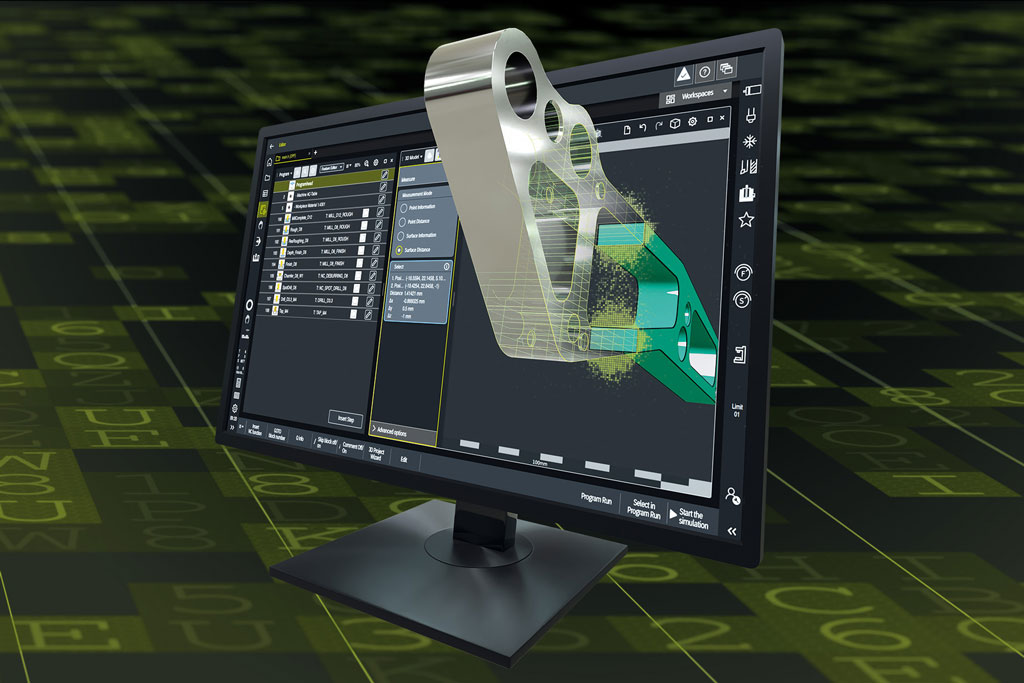

Faster from design to finished part with the vTNC7 programming system

The vTNC7 programming system is the next generation of the programming stations for creating NC programs to be used on HEIDENHAIN controls. In 2.5D applications, users of the vTNC7 software mainly profit from the programming process for one-off parts and small-batch runs, which helps users move faster from initial design to finished parts.

New functions of the TNC7 and introducing the TNC7 go

By expanding the range of functions and the product portfolio of the TNC7 controls, HEIDENHAIN opens up new areas of application and machining technologies for machine manufacturers and users.

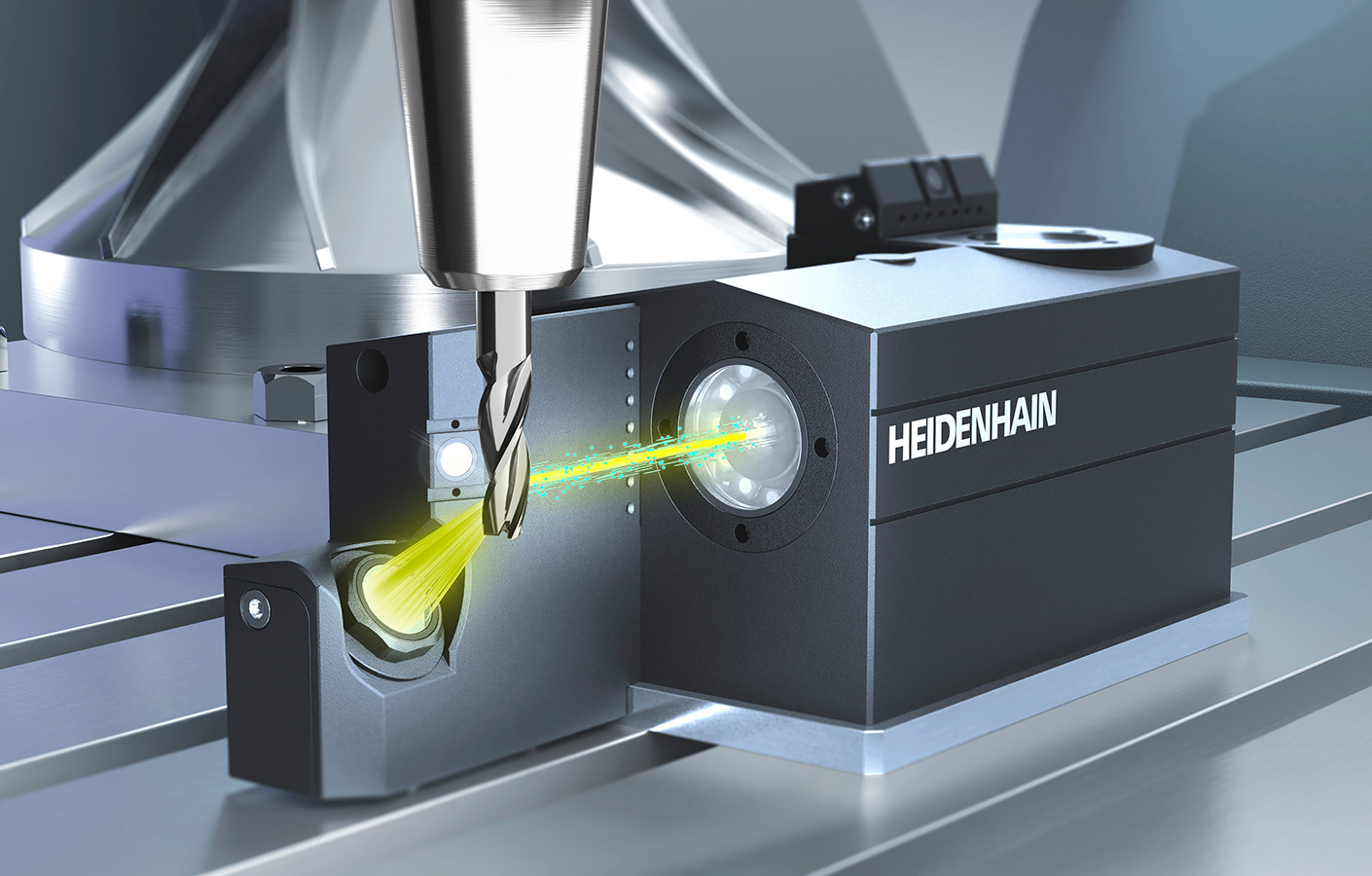

The VT 122 camera and the Visual Tool Check software form a measuring system for holistic evaluation of tools. They combine three tasks in one system: tool presetting, tool magnification, and visual tool inspection.

The use of coolant during machining leads to condensation and liquid contamination in the machine tool. But the sealed series 6 LC linear encoders and the series 1 RCN angle encoders with integral bearing from HEIDENHAIN deliver clear scale readings despite contamination. The innovative TRUE IMAGE TECHNOLOGY ensures this.

HEIDENHAIN and its brands AMO, RENCO and RSF will be showcasing innovative motor feedback solutions for robots and cobots at AUTOMATICA 2025 in Munich, Germany

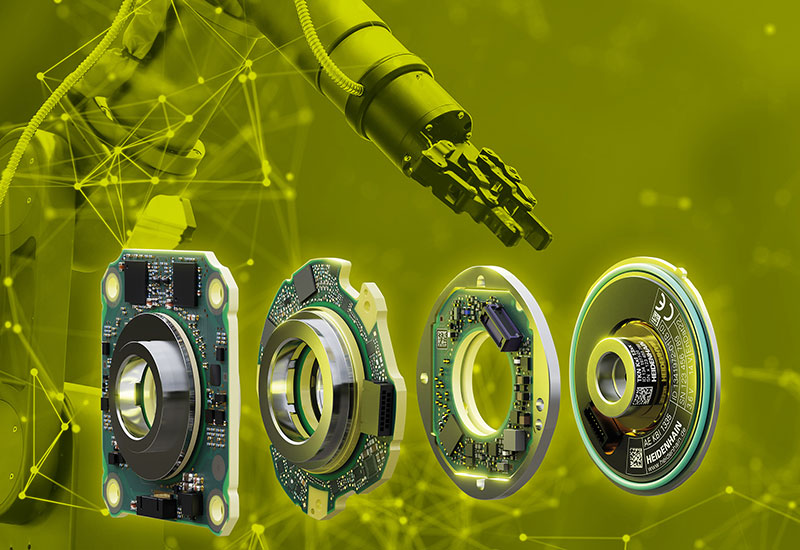

At SPS 2024 in Nuremberg, Germany, HEIDENHAIN and its brands AMO, RENCO and RSF will be showcasing encoders for the full spectrum of robotics and automation applications. Among the highlights are dual encoders and secondary encoders for advanced robotics, as well as inductive rotary encoders with added functionality.

Make your shopfloor processes more visible by collecting, analyzing and visualizing CNC machine status data in real time with the HEIDENHAIN StateMonitor software. Its machine data collection capabilities now include two new features: enhanced energy data analysis and connectivity to ERP and MES software for automated data sharing.

Tool presetting, tool magnification, and visual tool inspection: the VT 122 measuring camera and the VTC software from HEIDENHAIN are an intelligent system for all three tasks. The length and diameter of tools are measured automatedly.

“Stairway to sustainability: more productivity from the first part” is the HEIDENHAIN motto at its AMB trade show exhibit, where visitors will find a variety of solutions that unlock greater productivity, quality and process reliability.

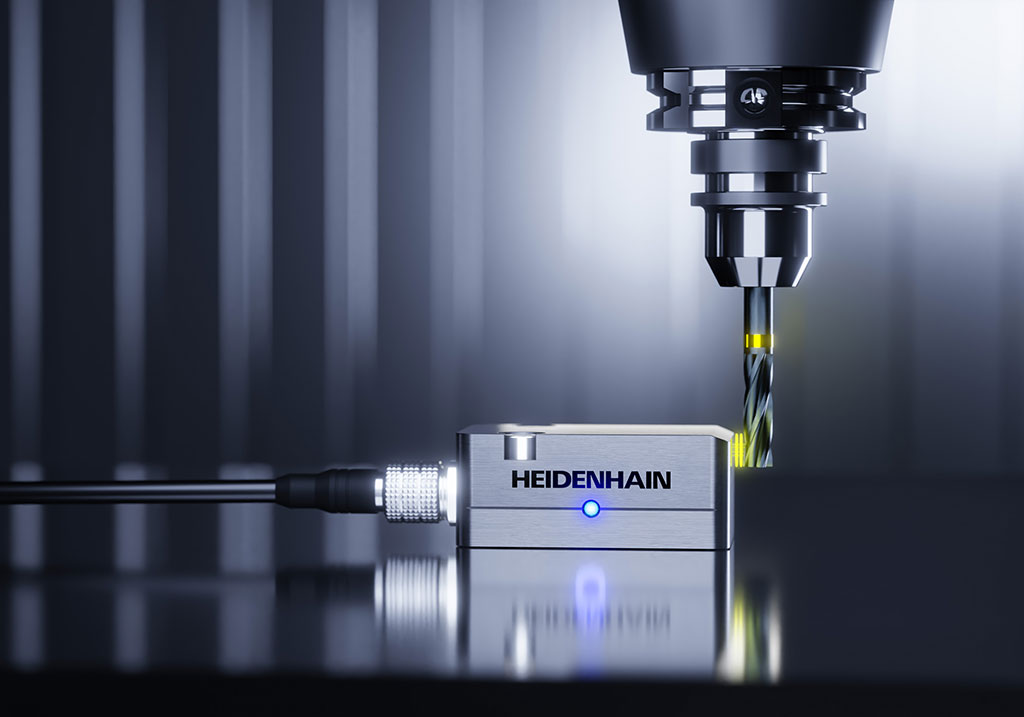

Perform on-machine tool breakage inspection that seamlessly integrates into your automated processes. The HEIDENHAIN TD 110 tool breakage detector provides two essential sustainability benefits: significant time savings and minimized scrap, resulting in greater productivity from the very first part.

“Stairway to sustainability: more productivity from the first part” is the HEIDENHAIN motto at its AMB trade show exhibit, where visitors will find a variety of solutions that unlock greater productivity, quality and process reliability.

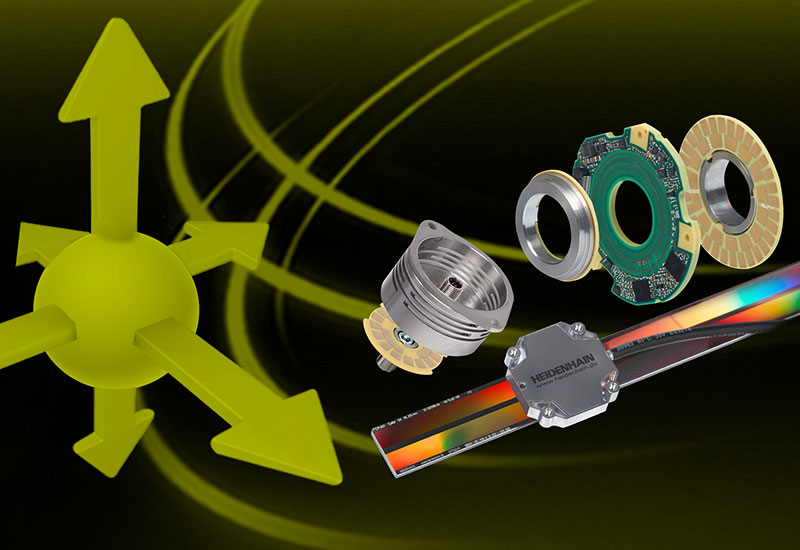

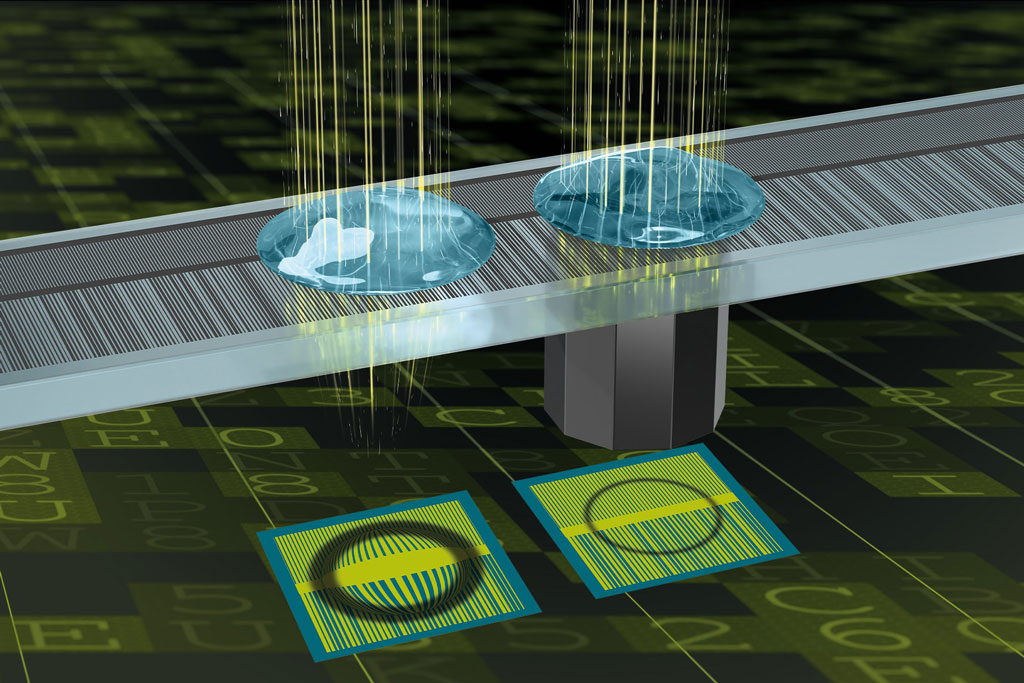

Encoders with MULTI-DOF TECHNOLOGY can capture up to six degrees of freedom in addition to their primary axis of measurement. Due to their multi-dimensional feedback, these encoders are known by the designation “Dplus”.

The HEIDENHAIN booth at SPS Italia 2024 is presenting two main topics: new products for highly-demanding automation technology, such as the ECI 123 Splus rotary encoder with built-in vibration analysis, and the assumption of sales activities for the LEINE LINDE and LTN brands at HEIDENHAIN ITALIANA.

Featuring a built-in accelerometer, the new HEIDENHAIN ECI 123 Splus rotary encoder enables position measurement and vibration analysis in a single component. This added functionality simplifies condition monitoring and maintenance planning in high-wear automated systems.

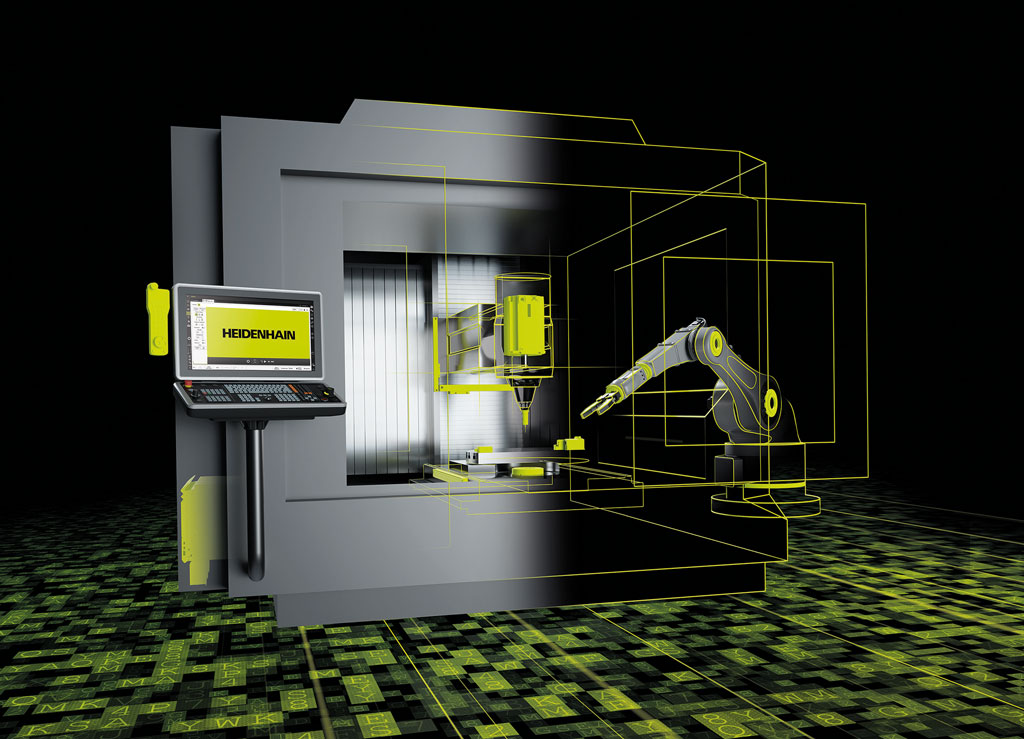

The challenge of automation runs deeper than complex production systems with robots and a pallet pool. It’s also about perfectly tuned workflows that ensure reliable processes. HEIDENHAIN offers effective solutions.

Workpiece inspection is very important both during and after machining. The new generation of METRO and SPECTO length gauges from NUMERIK JENA provides production metrology and quality inspection with many benefits that ensure the delivery of perfect products to customers.

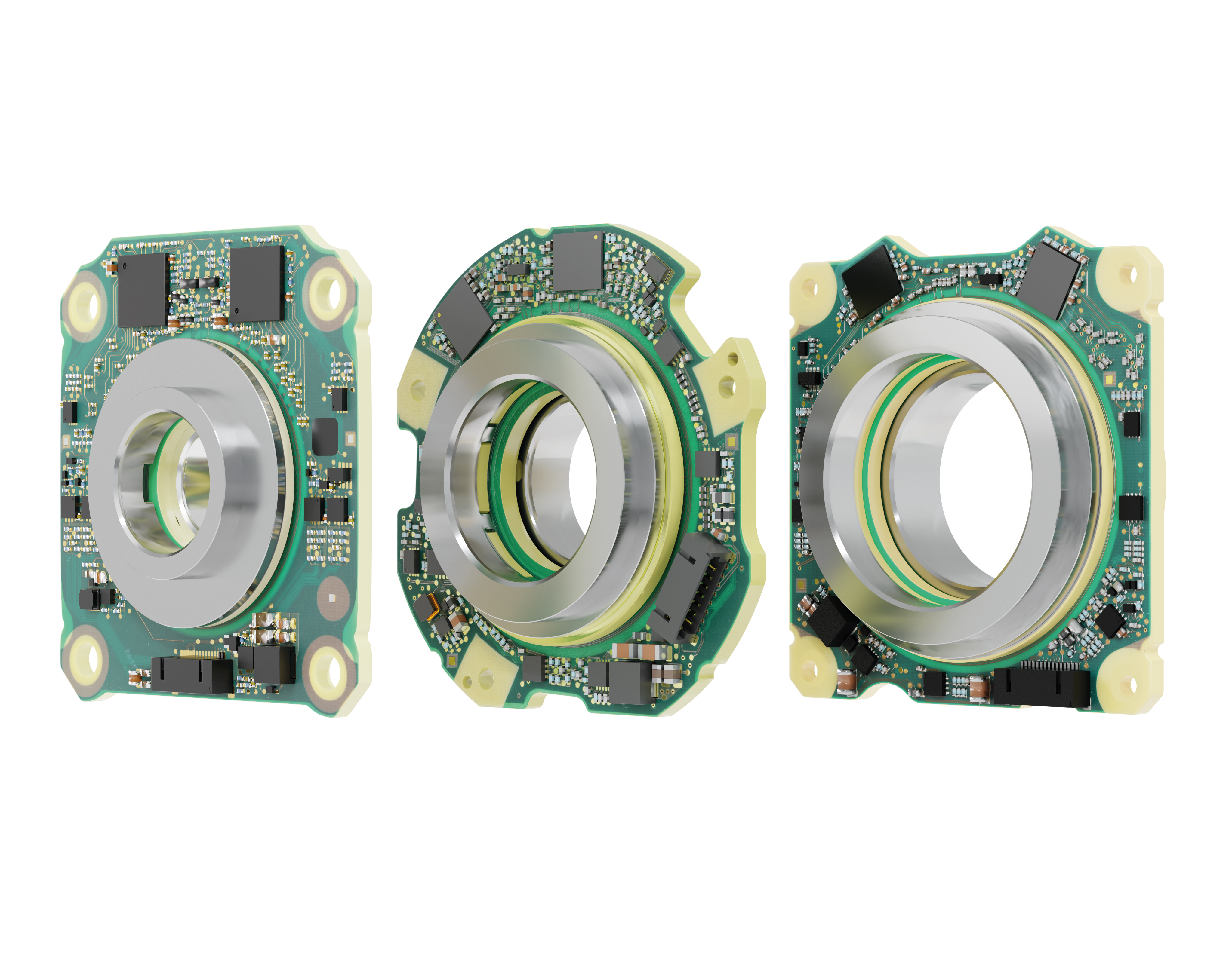

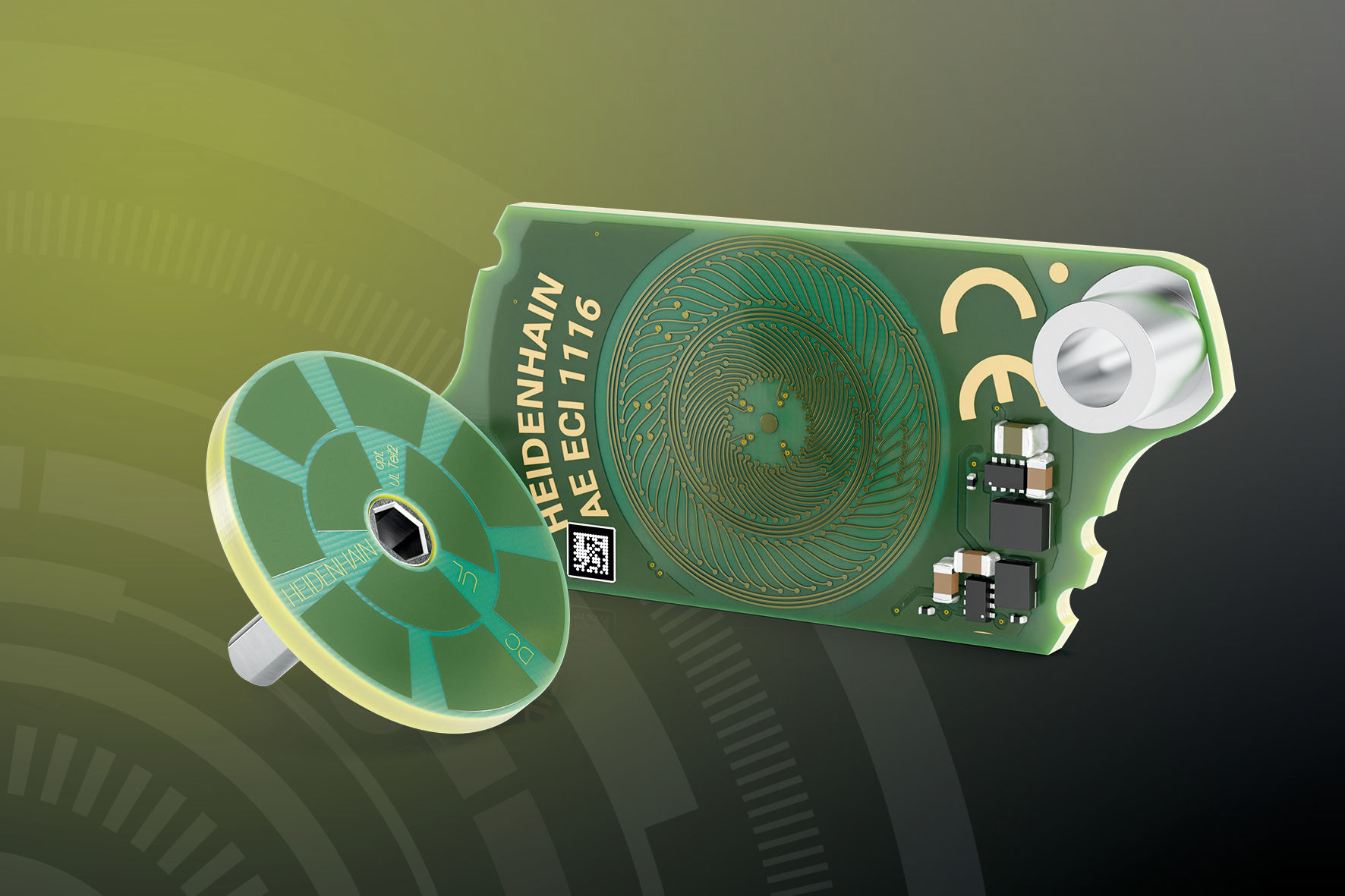

HEIDENHAIN is showcasing its next generation of inductive scanning technology, embodied in the ECI 1122 and EQI 1134 rotary encoders. Designed for high-performance automation, these new encoders feature low noise, low speed ripple and extensive operating data. Thanks to their EnDat 3 interface, they can be connected using the HMC 2 single-cable solution.

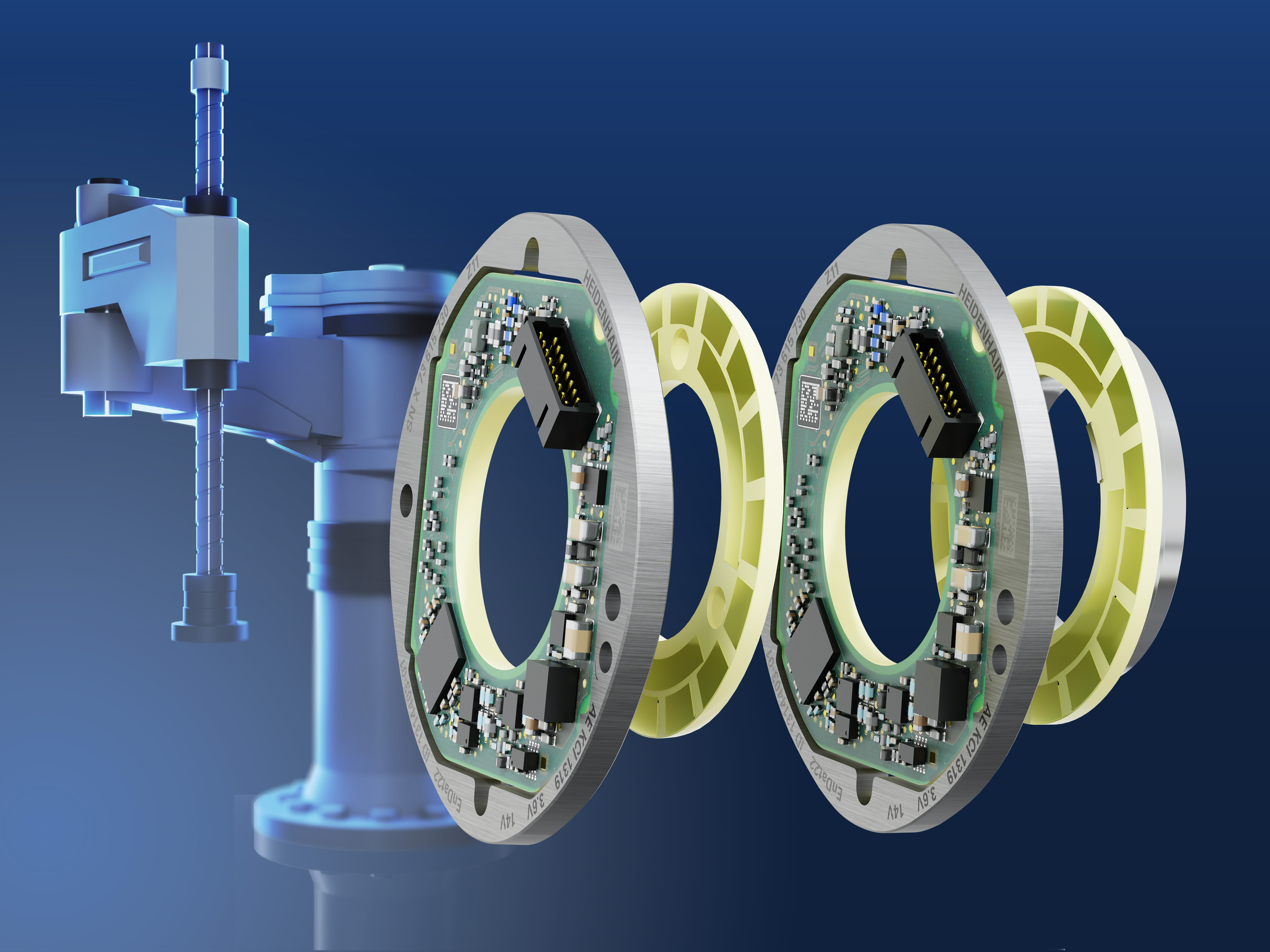

Robotics and other applications with compact motors stand to benefit from the KCI 1300 (singleturn) and KBI 1300 (multiturn) rotary encoders from HEIDENHAIN. Flat, lightweight and immune to both contamination and magnetic fields, these encoders feature a 25 mm hollow shaft and employ a scanning unit combined with either a screw-fastened circular scale or a press-fit disk/hub assembly. Wide mounting tolerances make installation easy. Mechanical fault exclusion ensures dependable mounting.

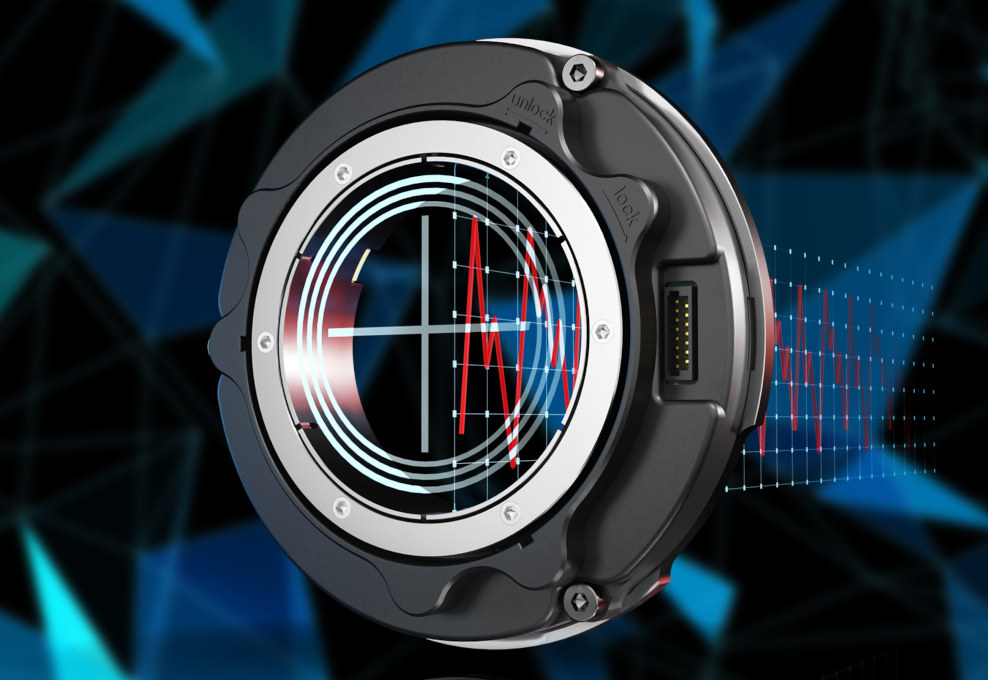

Discover a single device that provides position feedback from both the motor shaft and gearbox output shaft of a robot joint: the HEIDENHAIN KCI 120 Dplus dual encoder. Using robust inductive scanning technology, the encoder’s scanning head reads two separate circular scales for dual feedback. By measuring the gearbox output shaft, the KCI 120 Dplus can counteract design-induced inaccuracy on highly articulated and dynamic robots.

Intelligent encoders setting new standards in drive system technology

At its booth at SPS in Nuremberg and afterwards at its digital event for automation, HEIDENHAIN will be showcasing powerful solutions that set new standards in automation drive systems, including products from its brands AMO, ETEL, NUMERIK JENA, RENCO and RSF. Visitors will discover new inductive rotary encoder variants for robotics applications along with the next generation of inductive scanning.

New functions and improved features for shop-floor oriented production

HEIDENHAIN is presenting the next stage in development of the TNC7 at AMB 2022 in Stuttgart. Software version 17 of the next level in CNC control offers even more features that make working on the shop floor faster, easier and more reliable.

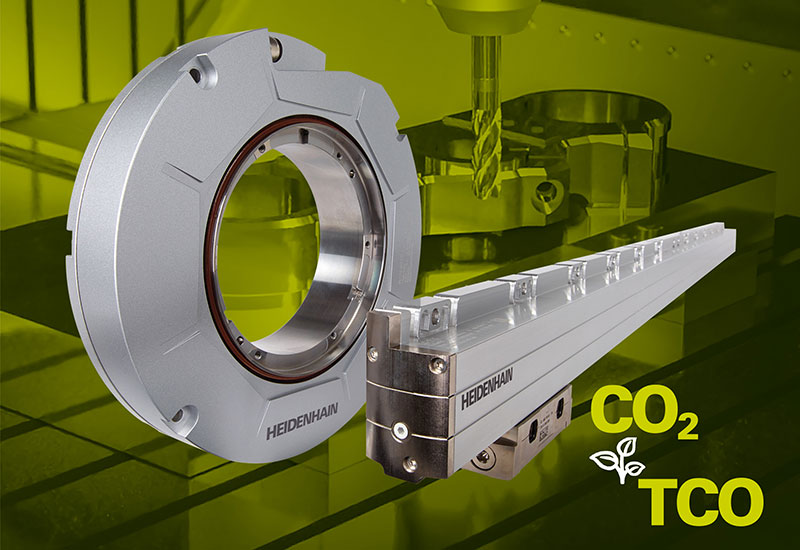

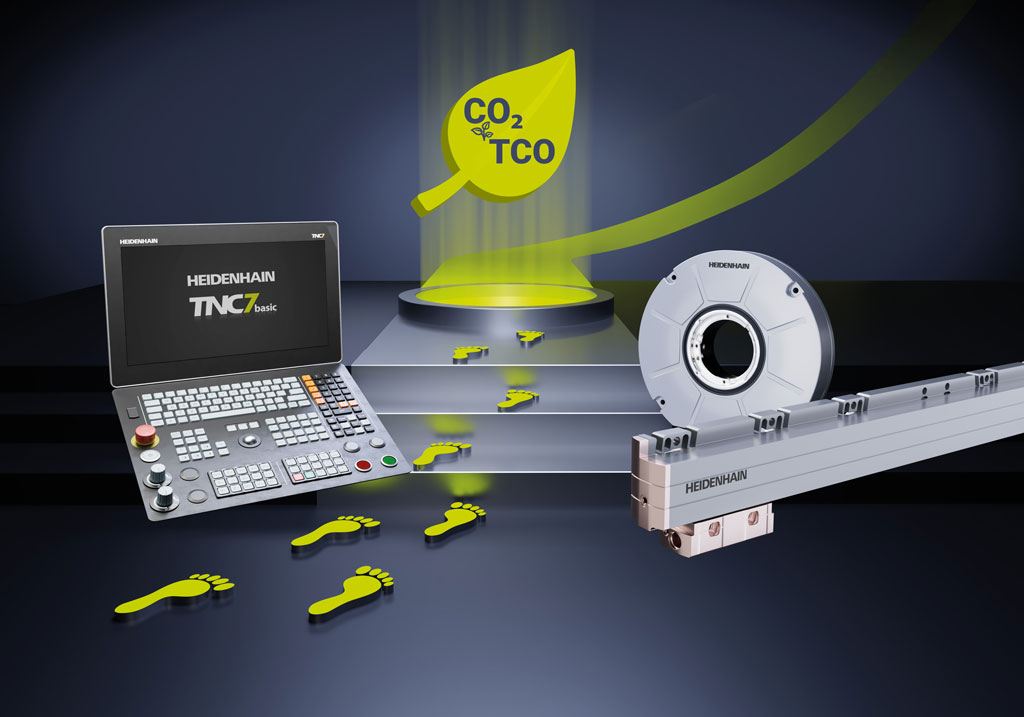

Sustainability and system costs, also referred to as Total Cost of Ownership (TCO), are trending topics for machinists and machine manufacturers in the machining world. At AMB, HEIDENHAIN is showing actual solutions to make machine tools more cost efficient through better utilization of resources.

Software, advising and services that advance your CNC machining

The Digital Shop Floor from HEIDENHAIN delivers practical solutions and competent services for complete digitalization, providing 360° of insight into manufacturing environments.

Performance, CO2 footprint and digitalization are trending topics for users and machine manufacturers in the machining world. At AMB, HEIDENHAIN will be presenting real-world solutions for the closely interrelated and often abstract requirements behind these terms.

A virtual trade show for automation will exhibit new solutions for robotics, medical technology, elevators, and more from HEIDENHAIN and its brands AMO, ETEL, NUMERIK JENA, RENCO, and RSF. Discover ultra-compact encoders and encoders with added functionality, offering numerous benefits especially in low-space applications.

In May, HEIDENHAIN and its brands AMO, ETEL, NUMERIK JENA, and RSF will be hosting their virtual trade show for metrology and quality assurance.

Grinding provides a path to perfect finishes. But this requires secure mastery of grinding processes and in-process monitoring of machining progress. This year, HEIDENHAIN will be a first-time exhibitor at GrindTec, presenting high-accuracy, robust solutions for machine manufacturers and operator-friendly grinding functions for the user on the TNC 640 control.

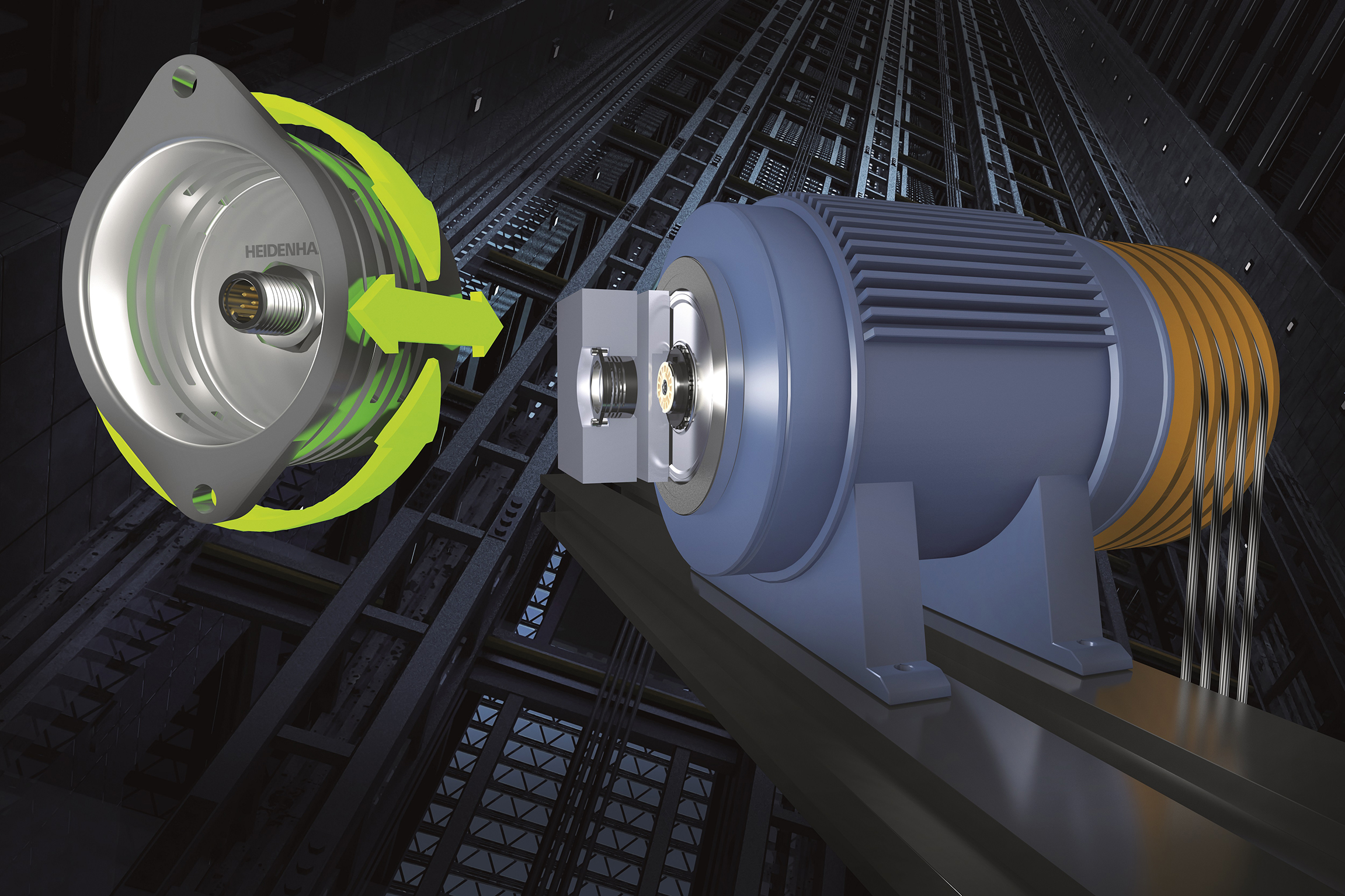

In the near future, cable-based elevator technology will no longer need microswitches for brake release monitoring. That’s because the new HEIDENHAIN KCI 419 Dplus rotary encoder for elevators provides not only position feedback for elevator motor control but also additional data for brake monitoring.

A single motor and a host of possibilities: Drives can be simply adapted to a wide variety of applications thanks to encoders from HEIDENHAIN, AMO, and RENCO.

HEIDENHAIN introduced two new TNC functions. Thanks to OCM, the user can program innovative milling strategies for any pocket and island directly on the TNC control. Meanwhile, new grinding functions round off the TNC 640’s capabilities for complete machining in a single setup.

Having command of highly complex procedures is a clear competitive advantage when it comes to milling and turning. Machine tools that are equipped with controls, encoders, and drive technology from HEIDENHAIN provide the best technical prerequisites.

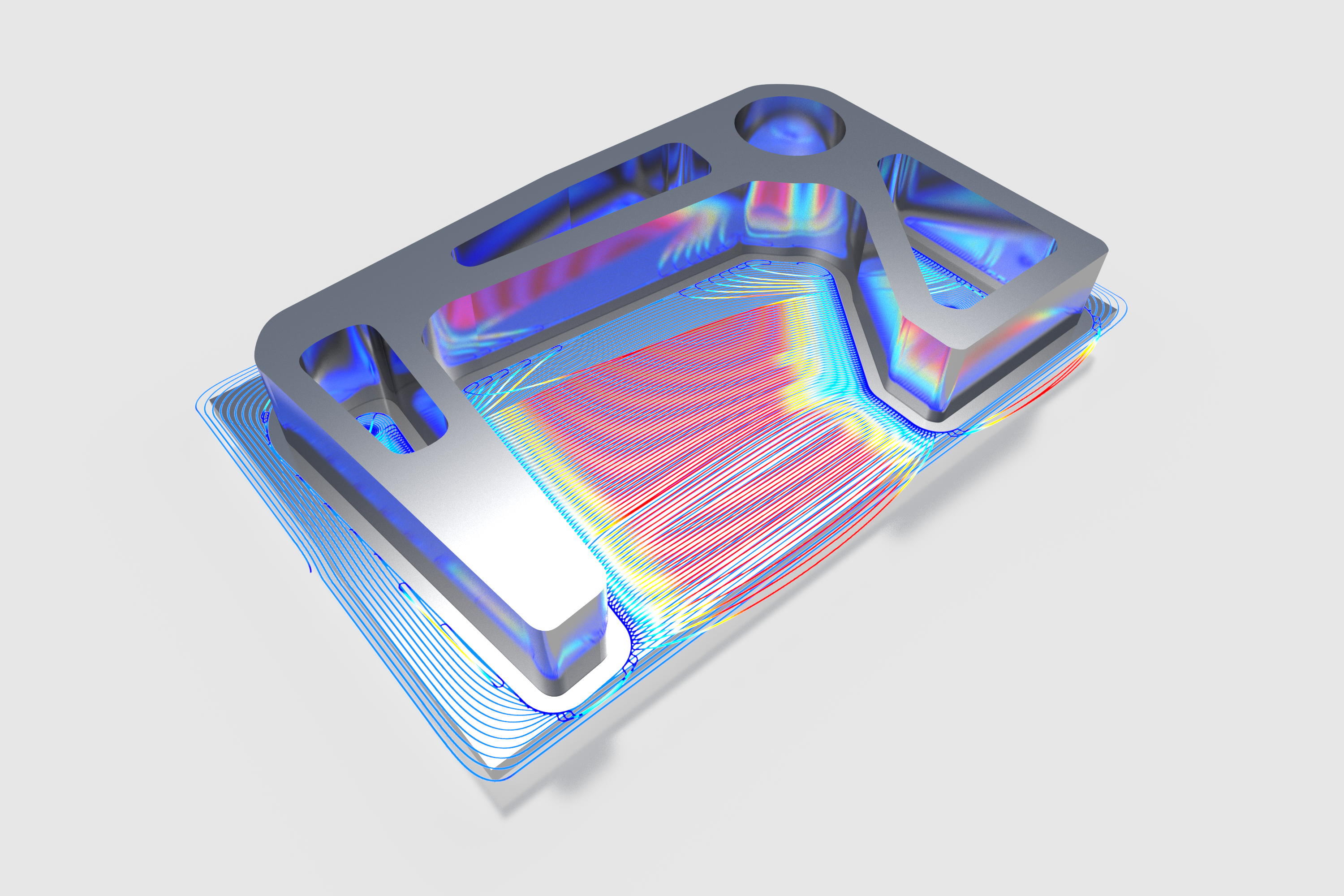

Deviations of the radius cutter's geometry from the ideal circular shape can negatively influence the surface quality and contour accuracy of a workpiece. With the aid of the powerful and three-dimensional tool-radius compensation option 3D-ToolComp and Cycle 444 PROBING IN 3-D offered by TNC controls, these deviations can be compensated for quickly and easily.

With the PWT 100 testing device and the PWM 21 inspection device from HEIDENHAIN, specialists for the repair and maintenance of machines and facilities have many highly practical options for displaying and evaluating this comprehensive information as well as for analyzing the encoders.

Bridges, wind turbines, cranes, and other similar large structures are subjected to particularly high loads. That’s why safe operation requires extensive monitoring. For this purpose, HEIDENHAIN and LEINE & LINDE will be introducing a new encoder series: the ESR strain sensors provide highly accurate digital measurement signals and are particularly easy to install.

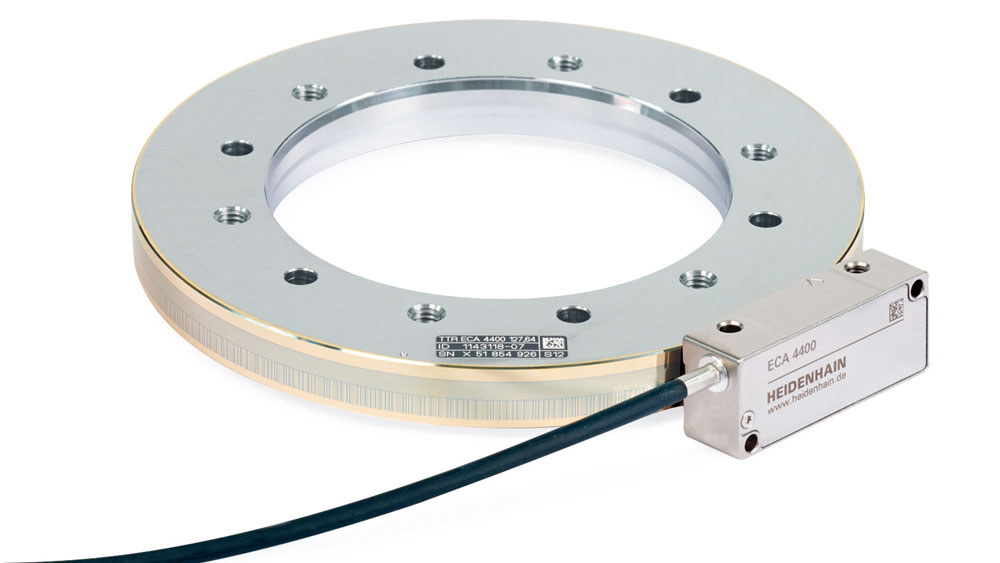

The ERP 1000 family of angle encoders was developed by HEIDENHAIN for applications requiring exceptionally constant speed control or high position stability at standstill.

HEIDENHAIN offers absolute rotary encoders with DRIVE-CLiQ interface* for position measurement in machines and production facilities with Siemens controls.

The HEIDENHAIN turning control CNC PILOT 640 has been impressing customers for many years with many advantages that facilitate the user's high-end turning operations. This is why it is becoming increasingly popular in applications that need to combine simple operation in the workshop with high production quality.

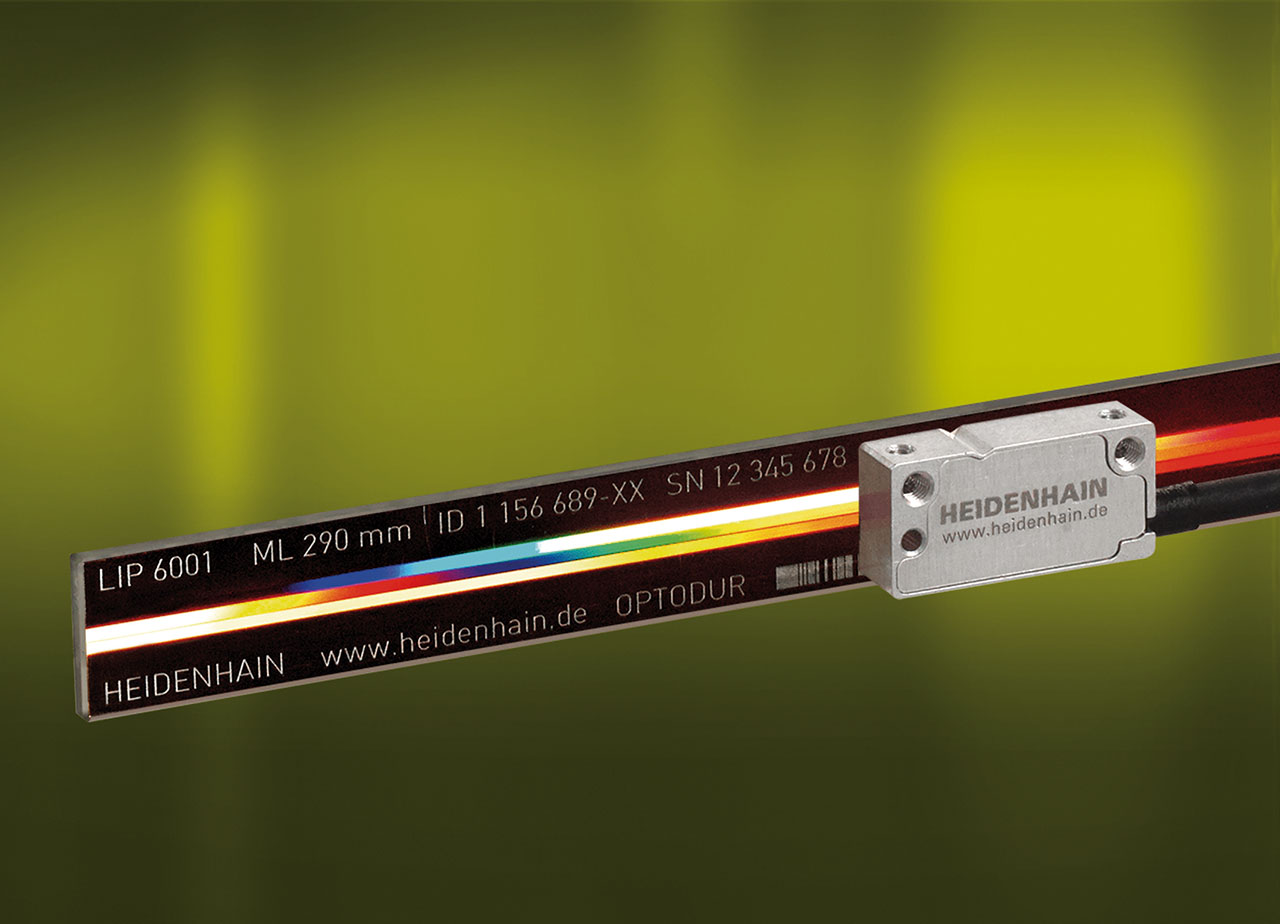

The LIP 6000 exposed linear encoder from HEIDENHAIN, featuring interferential scanning, enables exceptionally accurate position measurement as well as permanently reliable signals, all within in a compact design.

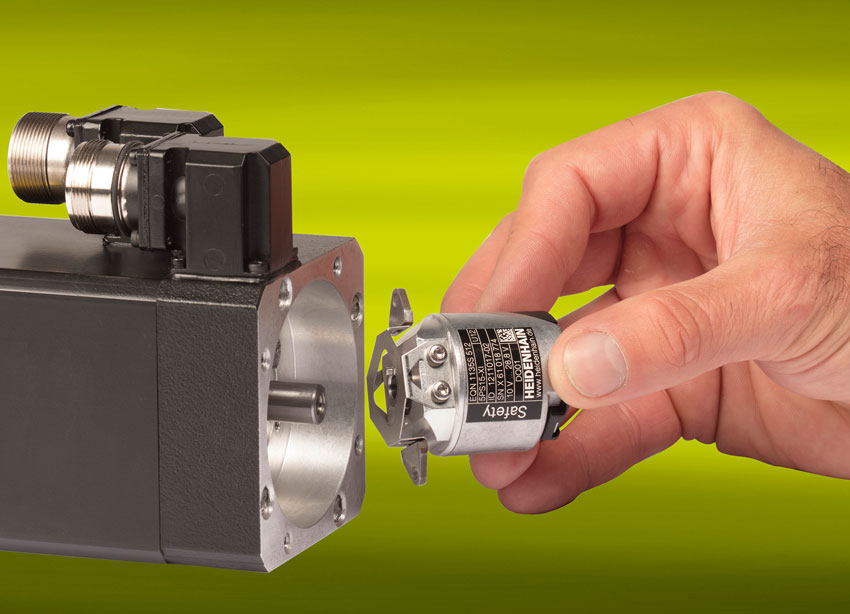

When using torque motors in machine tools, it is often necessary to classify the encoders for safety-related applications according to SIL 2 (as per EN 61 508) or performance level "d" (as per EN ISO 13849), because the rotational axes are usually operated with only one encoder.

Machine designs for the injection molding of plastics increasingly depend on hybrid or even all-electric drive technology. High-efficiency electric drives close the mold, dose, inject and dispense as well as actuate the frequently coupled extraction robot.

Your selected filter did not return any results.

![[Translate to English:] [Translate to English:]](/fileadmin/Bilder/04_News/Presse/HEIDENHAIN_SPS2024_Productrange_web.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/Bilder/04_News/Presse/1_HEIDENHAIN-MULTI-DOF_Technology6D_web.jpg)