Encoders for the elevators of the future: KCI 419 Dplus and LINA 200

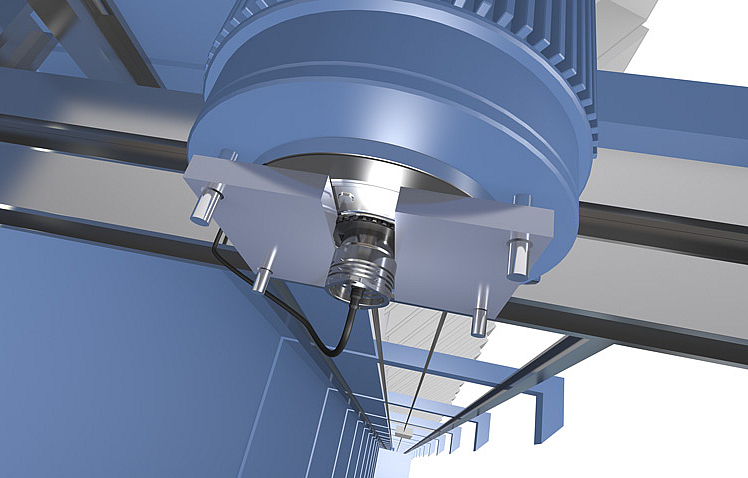

In the near future, cable-based elevator technology will no longer need microswitches for brake release monitoring. That’s because the new HEIDENHAIN KCI 419 Dplus rotary encoder for elevators provides position feedback for elevator motor control as well as additional data for brake monitoring.

In the more distant future, elevators will even run without cables. HEIDENHAIN presents an encoder solution for this as well: the LINA 200 absolute linear encoder.